Bespoke design developed and supported by our Mechanical and Software Engineers here in the UK.

The TRYAX TY series is ushering in a new era for diamond cut alloy wheels. This CNC vertical alloy wheel lathe is characterised by its innovative purpose built design. Built from the ground up both mechanically and electrically the system offers an easy to use touchscreen interface coupled with the latest state of the art real-time control software driving the latest in motion control digital drive technology.

Fitted with a 15.0" multi-touch screen which offers user-friendliness and precision coupled with reliability.

Other highlights such as a ultra-fast digitizing option , probing a typical 20” wheel in less than 3 minutes resulting in valuable savings in time for maximum wheel throughput.

Additional options for storage of wheel profiles and CCD camera support for storing images of wheels are available.

Mechanically a modern linear rail cross slide design is utilised, fitted to an inherently stable ribbed cast-iron frame.

Being of compact design the footprint of the TY-30VS saves on valuable floor space but is capable of cutting wheels from 14” to 30” in diameter.

Circular door design allows easy open accessibility to the working area, a steep sided work area floor guides the aluminum swarf to the catcher.

Finally piece of mind that the system has been developed and supported by our engineers here in the UK with

PROVEN REAL WORLD TECHNOLOGY FOR THE ALLOY WHEEL REFURBISHMENT INDUSTRY

A intuitive man machine touchscreen interface.

Simple 2 Stage process, digitise wheel then cut wheel, no need to transfer data backwards and forwards to an offline PC as required by other manufactures offerings.

Stage 1 Digitise…

Stage 2 Cutting…

Videos

.

Testimonials received by our UK sales agents Mint Alloys.

"I travelled all corners of the UK and had lots of demos but the Mint Alloys machine was streets ahead"

"We chose Mint Alloys to supply our equipment because they had designed and buily a bespoke lathe spcifically for alloy wheels.

The simplicity of operation and ease of use allowed our staff to be fully trained by the end of day one"

"We researched the market very carefully as there are a number of suppliers and we chose Mint Alloys for a number of reasons;

. The quality of the product

. The back-up and support available

. The training and

. The performance of the equipment in use"

"Dealing with Andy and the

team at Mint Alloys has proven to be a seamless experience. Their knowledge about the machine and wheel refurb business is second to none"

"The ongoing customer service from Andy at Mint Alloys has been amazing.

I would recommend the machine and Mint Alloys as a company to anyone"

"Buying our diamond cutting lathe from Mint Alloys was one of the best decisions we have ever made for our business. The lathe itself, with integrated computer system, is very intuitive and incredibly simple to operate"

"The Mint Alloys machine is perfect for our business. competitivley priced, easy to use and produces a great finish, we could not ask for more. Classic Coatings fully endorse this machine"

"One of the real advantages of using Mint Alloys as a company is that they also refurbish alloy wheels as wellas supplying lathes. This means we can discuss any technical issues regarding refinishing diamond cut alloy wheels on the same level"

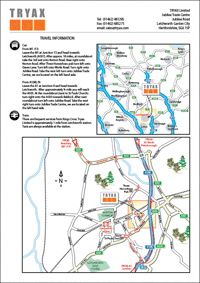

Travel Information

By car from M1 J13:

Leave the M1 at Junction 13 and head towards Letchworth (A507)

After approx. 18 miles, at roundabout take the 3rd exit onto Norton Road

Bear right onto Norton Road

After Three Horseshoes pub turn left onto Green Lane

Turn left onto Works Road

Turn right onto Jubilee Road

Take the next left turn onto Jubilee Trade Centre, we are located on the left hand side.

By car from A1(M) J9:

Leave the A1 at Junction 9 and head towards Letchworth

After approximately ¾ mile you will reach the A505

At the roundabout (next to St Pauls Church) turn right onto the A505 towards Baldock

After next roundabout turn left onto Jubilee Road

Take the next right turn onto Jubilee Trade Centre, we are located on the left hand side.

By train:

There are frequent services from Kings Cross

Tryax Limited is approximately 1 mile from Letchworth station

Taxis are always available at the station.

Postal Address

Tryax Limited

Jubilee Trade Centre

Jubilee Road

Letchworth Garden City

Hertfordshire

SG6 1SP

UK

Tel: +44 (0)1462 481 295

Fax: +44 (0)1462 685 275